Natural gypsum

Contents |

[edit] What is natural gypsum?

Natural gypsum is a soft sulphate mineral with the chemical formula CaSO4·2H2O, also known as calcium sulphate dihydrate. It consists of calcium, sulphur bound to oxygen, and water. It is an abundant mineral in sedimentary rocks that has been mined and used for construction and as a fertiliser since the time of Ancient Egypt.

[edit] Natural occurrence

The mineral gypsum was formed around 200 million years ago due to the evaporation of sea water, leaving layered deposits of calcium sulphate dihydrate, under high pressure and temperature the gypsum turns into anhydrite (CaSO4). The sedimentary rock contains varying amounts of gyspum, (around 75% to 95%), with the remaining being clay and chalk.

Gypsum and anyhdrite can occur in masses up to a few metres thick and are often mined in conjunction with one another. Gypsum has a considerably greater number of applications although finely ground and blended anhydrite and gypsum are used in large quantities as part of the mix to produce cement clinker and Portland cement.

Pure gypsum is typically white, although impurities create a wide range of different colours. It is moderately water-soluble but exhibits retrograde solubility, meaning it becomes less soluble at higher temperatures. It is fire resistant and is effective at preventing the passage of sound.

[edit] Production and use

In terms of production, gypsum rock is mined or quarried and then crushed and ground into a fine powder. When natural gypsum (CaSO4,2H2O) is ground to a powder and heated at 150° to 165° C, the majority of its chemically combined water is removed, to produce a hemi-hydrate (a crystalline hydrate containing one molecule of water for every two molecules of its compound) plaster (CaSO4,1/2H2O), better known as Plaster of Paris.

When the dry powder is then again mixed with water, it forms a paste which can set hard as the water recombines to produce Gypsum again. This process of dehydration and rehydration can be repeated almost indefinitely, meaning gypsum in its pure form can be recycled indefinitely. The prohibiting factor to this is that it is most commonly used in combination with other materials as;

- Plaster.

- Plasterboard / wallboard.

- Blockwork.

- Mortar.

- Blackboard chalk.

- In the production of cement clinker for Portland cement (blended with anhydrite).

There are a number of different products that are being developed that make use of recycled materials by mixing them with varying degrees of purity, part of this process can also involve the production of what is called synthetic gypsum.

[edit] Land fill and recycling

Gypsum itself can be recycled in a closed loop, meaning it can be recycled into the same product again, rather than down-cycled into another product. Danemark has some of the highest recycling rates in Europe with around 60% of gypsum being recycled. Whilst the European Union set a target of around 70%, countries such as Sweden, Norway, France and the UK are also gradually increasing their recycling rates. Though tonnages of recycled demolition waste are increasing, the proportion being recycled is not as high as the targets due to challenges surrounding contamination with other materials such as in plasterboard.

Once collected, plasterboards can be broken down into fine powders which can then be re-introduced, in controlled blends, to certain manufacturing processes. For closed loop recycling waste cycles, construction materials need to be pre-processed to remove nearly all other materials, as gypsum recyclers tend to accept only up to 3 per cent contamination.

Recycling gypsum waste reduces the need for virgin gypsum to be quarried and processed, which can mean significant energy and material savings for the processing of each metric ton, whilst gypsum found in landfilled plasterboard can decompose to release toxic hydrogen sulfide, and the paper can decompose to produce the potent greenhouse gas, methane.

[edit] Related articles on Designing Buildings

Featured articles and news

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction (HKIC) and The Chartered Institute of Building (CIOB) sign Memorandum of Understanding.

A detailed description fron the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

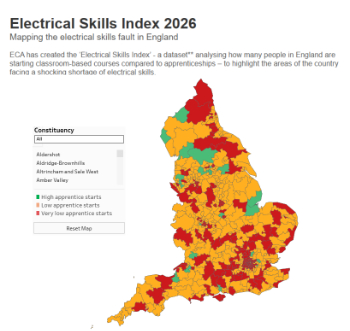

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

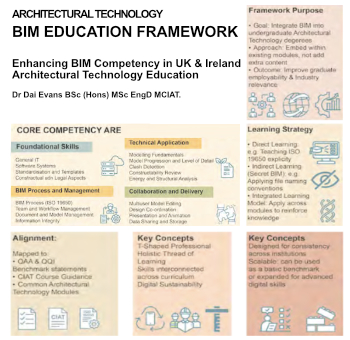

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Guidance notes to prepare for April ERA changes

From the Electrical Contractors' Association Employee Relations team.

Significant changes to be seen from the new ERA in 2026 and 2027, starting on 6 April 2026.

First aid in the modern workplace with St John Ambulance.

Solar panels, pitched roofs and risk of fire spread

60% increase in solar panel fires prompts tests and installation warnings.

Modernising heat networks with Heat interface unit

Why HIUs hold the key to efficiency upgrades.